By George Harper – 24th March 2022

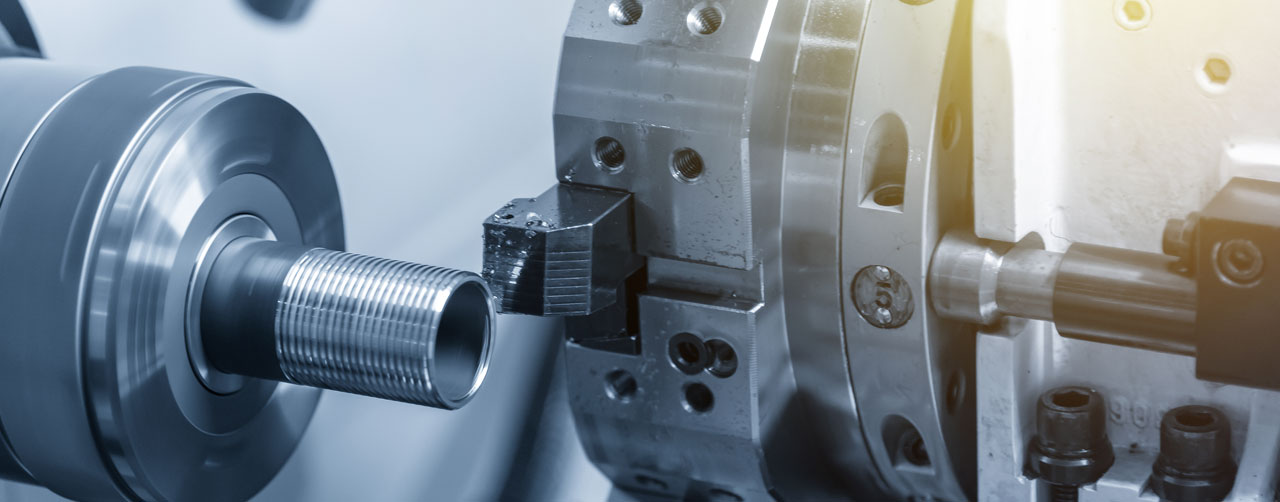

There is no doubt that CNC jobs are highly in demand in today’s job market. Precision engineered metalwork is used in almost every industry, from defence, aerospace all the way to consumer goods and medical equipment. With a forever rising population and an increasingly globalised world, the demand for products utilising parts made by CNC machines is only going to rise.

The industry has changed immensely over the last few years, particularly with the emergence of COVID-19, lockdowns and restrictions on workplaces. It has caused manufacturers to rethink the way they approach machining to account for circumstances such as these. There is an increasing focus on how robotics, machine learning and automation can drive production without the need for as much human intervention throughout the process.

This is particularly relevant for SME manufacturers as the technology to achieve this is becoming much more affordable and accessible. The employment trends that will ensue from this are highly anticipated and many professionals are wondering what this means for their CNC jobs. In this piece, we will take a look at the advanced and expected future of CNC machining, what this means for CNC jobs and what you can do to prepare yourself for the future.

Technological Leaps in CNC Machining

The last few decades have seen massive leaps in productivity and accessibility of CNC machines, particularly with the addition of 5 and now 7 & 9 axis milling machines, which enable micromachining and are capable of producing extremely detailed cuts at unmatched speeds. This has made 3 and 4 axis machines cheaper, both of which can also be modified into 5 axis machines. These advances mean that manufacturers are able to complete orders faster, more efficiently and more accurately.

The Automation Trend

Like many industries, the temptation to reduce your operating costs in CNC manufacturing is always in the background and will become a necessity when the majority of manufacturers go down the route of automation, robotics and machine learning. In an increasingly competitive market, where manufacturers are fighting for contracts, the ability to offer attractive pricing to clients will inevitably further encourage this push.

We are seeing ways to automate previously human tasks become more accessible to SMEs. Particularly in the loading and unloading of machines by tools such as the SherpaLoader, which allows for machining to carry on 24 hours a day and gives operators the ability to oversee larger clusters of machines; further making the machining process more efficient and cost-effective.

What this means for CNC Professionals

Sounds great, right? If you are a facility manager or production supervisor, then it probably does. But, if you are a CNC setter, CNC operator or CNC programmer, you might be wondering what this means for your ability to obtain and hold down CNC jobs into the future.

The prospect of many aspects of your role becoming automated may seem scary, but there are silver linings. With technology pushing CNC machining forward, manufacturers have the ability to take on more orders, which means expanding their operations.

There is an industry-wide problem of maintaining a steady stream of machine operators as old school machinists start to leave the workforce, along with making sure current operators are able to keep up with the capabilities of modern CNC machines. The way modern machines are trending currently means that they present problems and tutorials to the operator, allowing them to work more confidently and make fewer mistakes because they can interpret the signals the machine is giving.

What this means is that the technology is not yet in a place where CNC setters or CNC operators can be fully replaced and so these jobs are still in high demand. A well-versed CNC operator is a vital cog in the success of a machine shop and we are always looking for CNC Millers and CNC Turners to join our clients.

The Role of the CNC Programmer

With this in mind, the role of the CNC programmer is going to become ever more important going forward. These machines are going to require more in-depth programming, especially if you are adding automated loading and unloading steps into the manufacturing process, CNC programmer jobs are therefore expected to come at a premium as the skills required to do them well widens. If you are a programmer, we encourage you to become as familiar as possible with modern machines and controls.

Being equal parts operational and creative problem solving, CNC programmers are crucial to today’s manufacturing and according to the US Bureau of Labor Statistics, demand for this role is expected to increase by up to 16% by 2026.

One thing that we need to take into account with the development of automation in CNC manufacturing is that there will be a need for people that understand how to create and maintain these systems. If you are an experienced programmer that has a deep understanding of the processes, you will be setting yourself up for success for CNC jobs within a manufacturing environment that relies much less on human operation.

The Importance of Offline Programming

We should also take into account the transition to offline programming using CAD/CAM software such as SolidWorks, AutoCAD or EdgeCam. Much of the ageing workforce are CNC professionals with extensive experience in manual machining and programming. They are used to making programming as simple as possible using as few lines of code as necessary and so the use of CAM is something that a lot of old-school machinists are having a difficult time acclimatising to. That is not to say this is a bad thing, a large amount of machining is still done using manual programming and it is a skill that is highly sought after.

As machine shops are starting to begin taking the benefits of offline programming seriously, seeing decreased cycle times and improved tool longevity is only going to further encourage adoption. As this trend continues there is going to be a demand for skilled offline programmers and so if this is something that someone searching for CNC jobs has on their CV, it is only going to make them more attractive to employers with their sights set on the future of precision machining.

Our Advice for the Future

Clearly, the manufacturing industry is going to change rapidly over the coming decades, especially in regard to CNC machining. As a CNC professional you should be prepared for the push toward automation and less of a need for operators in the future. Here are our top tips to prepare for continuing to obtain and hold CNC jobs:

-

- 1. Get as much experience as possible working with CNC machines, gain a deep understanding of how they work and how to troubleshoot so that you have a skill set that is transferable to just operating them. If they become automated to a point where they no longer need operators then the need for professionals to maintain, service and troubleshoot them will grow.

-

- 2. As the role of the CNC programmer is going to become more important as the industry changes, getting qualifications in advanced engineering and becoming proficient with CNC programming languages will set up more attractive CNC job prospects; It will be worth the investment of your time and money.

-

- 3. Take any chance you can to become familiar with CAD/CAM modelling and simulation so that you can add a highly sought after skill that is going to make you stand out above the competition.

-

- 4. If you are in a position where you have access to more automation opportunities in CNC manufacturing, embrace them. They are clearly going to alter the way the industry approaches manufacturing processes and so being an early expert on them is only going to help future proof your place within it.

- 5. Our main piece of advice here is to view your CNC job as an “open-door†opportunity in the world of machining and metalwork. Spend time learning and perfecting your craft and you will start to see that precision metalwork is a huge umbrella under which many trades coexist. Having an open mindset to your CNC career will only place you at the front of the ranking as new paths open within the manufacturing industry.